– –

Sikandra Industries are established in the year 1990. We are one of the leading manufacturer and exporter of superior quality Process Plant Equipment to our clients across the globe. Our comprehensive range of products includes Heat Exchanger, Heater for Textile Processing Machine,Tray Dryer for Chemical Industries, Dryer for Pharmaceutical Machinery, Heat Exchanger for Food Processing Machinery, Laminate Heaters, Dryer for Salt Industries, Shell & Tube Heat Exchanger, Baby Steam Boiler, Blower, Hot Air Unit, Finned Tubes, Heating Element, Oil Cooler for Earth Moving Machinery, Oil Cooler for Hydraulic Machinery, Dryer Heater & other Industries. Our organization is supported with a state-of-the-art infrastructure facility, which is spread across a sprawling area. This unit consists of advanced manufacturing unit, quality testing unit, and warehousing and packaging unit. These units are managed by a team of highly experienced professionals who are qualified and experienced. With the support of these personnel we are able to offer an unmatched range of products to our clients. We also check the quality of these products to offer defect free range to our clients. Under the guidance of our mentor, Mr. Sikandar Mohan Singh (CEO), we are able to capture the demands of our clients within the stipulated time frame. His industry experience and ability to cater the demands of clients help us in offer superior quality range to our clients.

– –

Sikandra Industries are established in the year 1990. We are one of the leading manufacturer and exporter of superior quality Process Plant Equipment to our clients across the globe. Our comprehensive range of products includes Heat Exchanger, Heater for Textile Processing Machine,Tray Dryer for Chemical Industries, Dryer for Pharmaceutical Machinery, Heat Exchanger for Food Processing Machinery, Laminate Heaters, Dryer for Salt Industries, Shell & Tube Heat Exchanger, Baby Steam Boiler, Blower, Hot Air Unit, Finned Tubes, Heating Element, Oil Cooler for Earth Moving Machinery, Oil Cooler for Hydraulic Machinery, Dryer Heater & other Industries. Our organization is supported with a state-of-the-art infrastructure facility, which is spread across a sprawling area. This unit consists of advanced manufacturing unit, quality testing unit, and warehousing and packaging unit. These units are managed by a team of highly experienced professionals who are qualified and experienced. With the support of these personnel we are able to offer an unmatched range of products to our clients. We also check the quality of these products to offer defect free range to our clients. Under the guidance of our mentor,Mr. Sikandar Mohan Singh (CEO), we are able to capture the demands of our clients within the stipulated time frame. His industry experience and ability to cater the demands of clients help us in offer superior quality range to our clients.

Infrastructure

Quality Assurance

Team

– –

These types of fins are semi-crimped and wrapped under tension around the outside of the base tube….Continue

A baby steam boiler is a small-capacity steam generator used for low-pressure applications. It is commonly….Continue

Hot Thermic oil is used as heating media. Air is heated by hot Thermic oil….Continue

In Hydraulically operated machines all functions are done with pressurized hydraulic oil This oil becomes hot…..Continue

A Hot Air Unit is a system used to generate and circulate heated air for various industrial and commercial….Continue

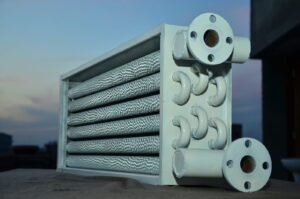

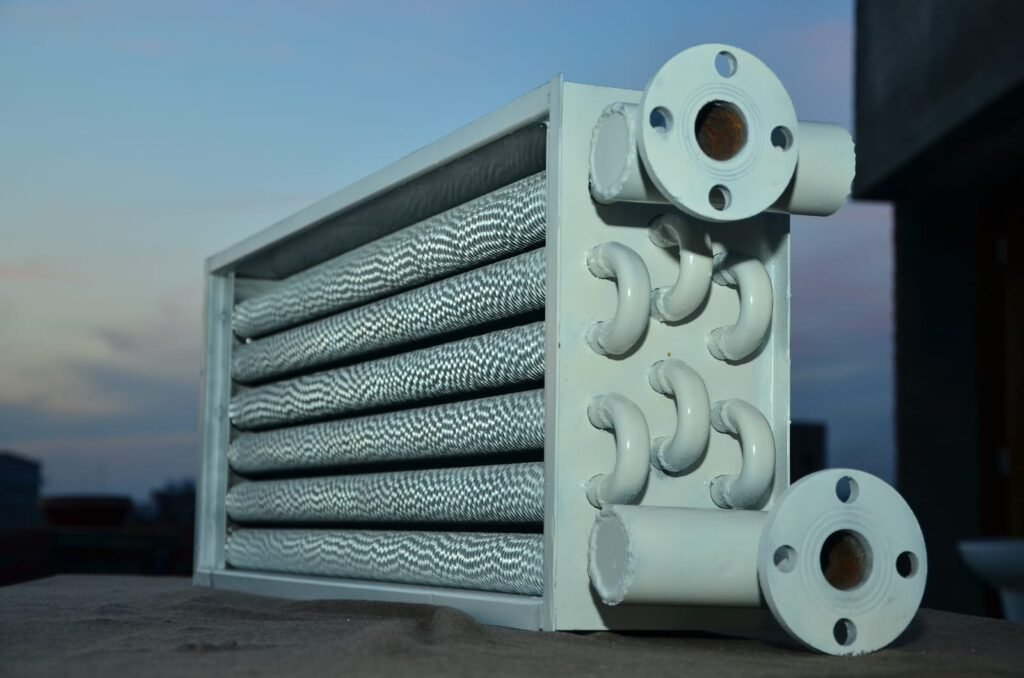

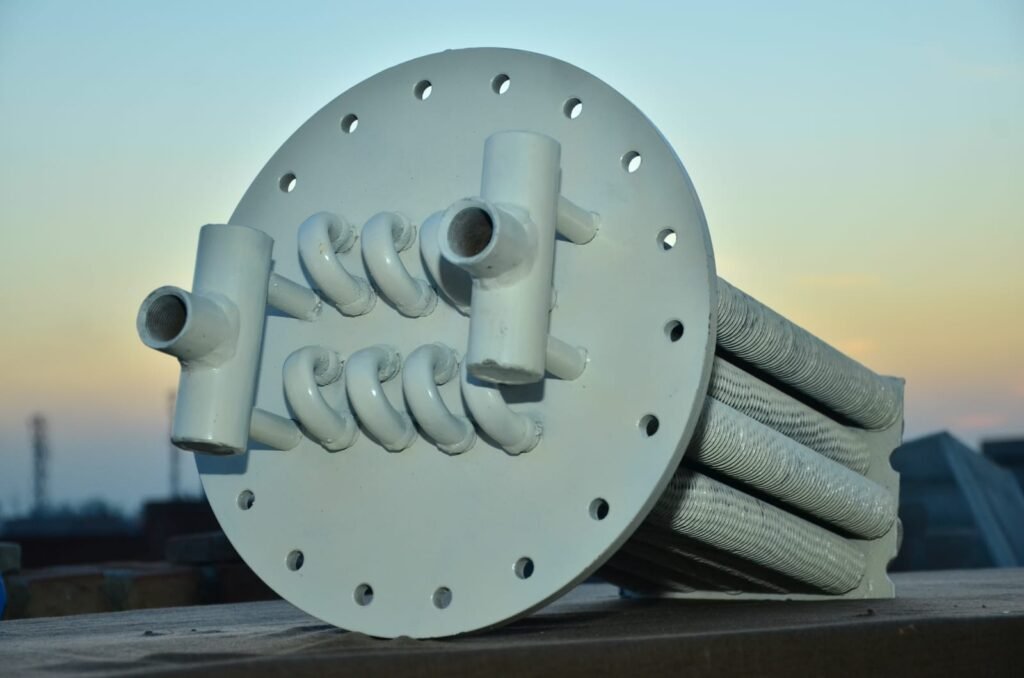

Tubes used may be ERW or Seamless depending on steam pressure in tubes…..Continue

– –

These types of fins are semi-crimped and wrapped under tension around the outside of the base tube….Continue

Tubes used may be ERW or Seamless depending on steam pressure in tubes…..Continue

Hot Thermic oil is used as heating media. Air is heated by hot Thermic oil….Continue

In Hydraulically operated machines all functions are done with pressurized hydraulic oil This oil becomes hot…..Continue

A Hot Air Unit is a system used to generate and circulate heated air for various industrial and commercial….Continue

A baby steam boiler is a small-capacity steam generator used for low-pressure applications. It is commonly….Continue

Company Insights

You should only pick the keywords that are both popular with people and ones that you’re also able to rank for. Brian Dean actually recommends creating content specifically for the people for the house.

–

–

–

–

–

–